Commercial bullet ice makers are a staple in various high-demand industries, including hospitality, healthcare, and food service. Their ability to produce chewable, slow-melting ice makes them ideal for a wide range of applications. However, how do these machines meet the diverse and often stringent requirements of different industries, and what features make them adaptable to such varied environments?

Customizable Ice Production

One of the key features that make commercial bullet ice makers versatile is their ability to produce ice in customizable sizes and quantities. Different industries have different ice requirements; for example, healthcare facilities may need smaller, chewable ice for patient comfort, while bars and restaurants may require larger quantities for beverages. Modern ice makers offer adjustable settings that allow users to control the size and output of the ice, ensuring that the machine can be tailored to meet specific needs.

High Production Capacity

High-demand industries require ice makers that can produce large quantities of ice quickly and efficiently. Commercial bullet ice makers are designed with high production capacities, often capable of producing hundreds of pounds of ice per day. This ensures that businesses can meet their ice demands without interruption, even during peak periods. Additionally, some models feature storage bins with large capacities, allowing for the accumulation of ice reserves that can be used as needed.

Energy Efficiency and Sustainability

With increasing emphasis on sustainability, energy efficiency has become a critical consideration for businesses. Modern commercial bullet ice makers are designed to minimize energy consumption without compromising performance. Features such as energy-efficient compressors, insulated storage bins, and smart sensors that optimize ice production cycles contribute to lower energy usage. This not only reduces operational costs but also aligns with the sustainability goals of many industries.

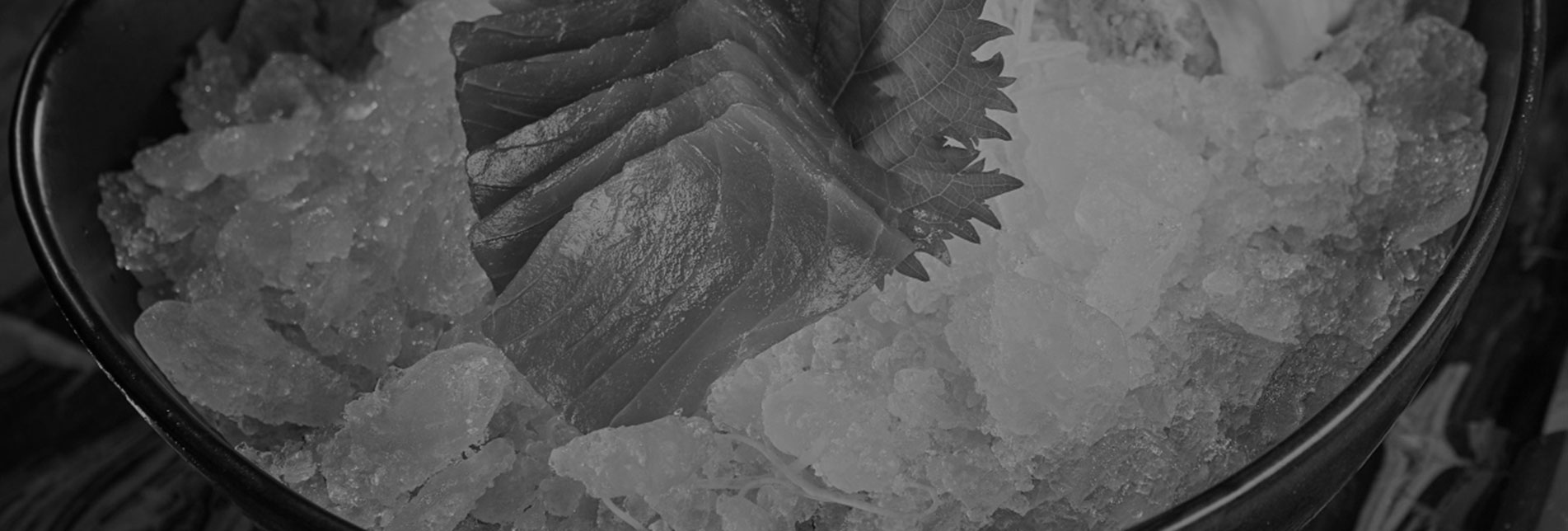

Hygiene and Food Safety

In industries such as healthcare and food service, hygiene and food safety are paramount. Commercial bullet ice makers are equipped with features that ensure the ice produced is safe for consumption. Advanced water filtration systems remove impurities and contaminants, while antimicrobial components prevent the growth of bacteria and mold. Additionally, automated cleaning and descaling programs maintain the internal hygiene of the machine, reducing the risk of contamination.

Durability and Reliability

High-demand industries require equipment that can withstand continuous use and harsh conditions. Commercial bullet ice makers are built with durability in mind, using high-quality materials such as stainless steel and robust plastics. These materials resist corrosion and wear, ensuring that the machine remains operational even in challenging environments. Furthermore, the internal components are designed for reliability, with features such as overload protection and self-diagnostic systems that prevent breakdowns and extend the machine's lifespan.

Compliance with Industry Standards

Different industries have specific regulations and standards that must be met. Commercial bullet ice makers are designed to comply with these standards, ensuring that they are suitable for use in various settings. For example, models used in healthcare facilities may need to meet specific hygiene and safety standards, while those used in food service must comply with food safety regulations. Manufacturers often provide certifications and documentation to verify compliance, giving businesses peace of mind.

User-Friendly Design

Ease of use is another important consideration, especially in high-demand environments where staff may not have the time or expertise to operate complex equipment. Modern commercial bullet ice makers feature user-friendly interfaces with intuitive controls and clear displays. Additionally, many models come with remote monitoring and control capabilities, allowing operators to manage the machine's performance from a distance.

English

English Español

Español